This page highlights the Peckett project. AIM: To make a model to represent the Peckett at Puffing Billy in On30. Entries are from oldest to newest.... |

|

|

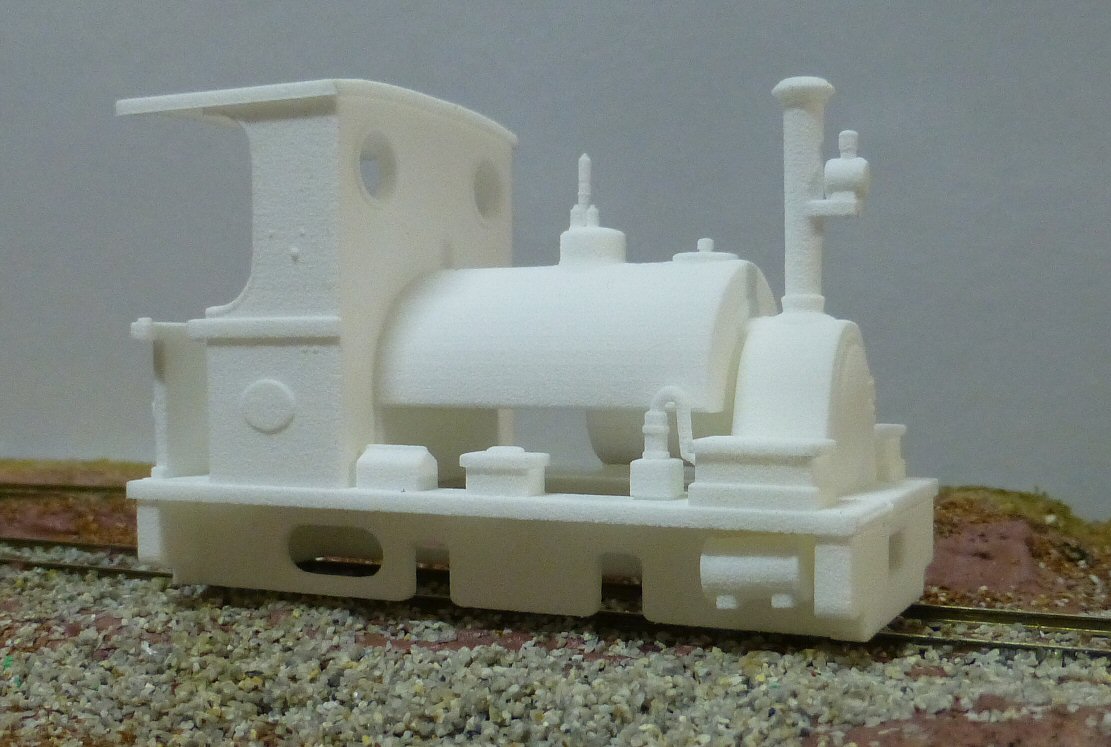

This year I purchaed a few shapeways 3D printed models of several PBR locos. But one I wanted, the PBR Decauville #861 would not print,as the V didn't either. So that's when I ordered the Peckett. It printed and that was the start of this project. |

|

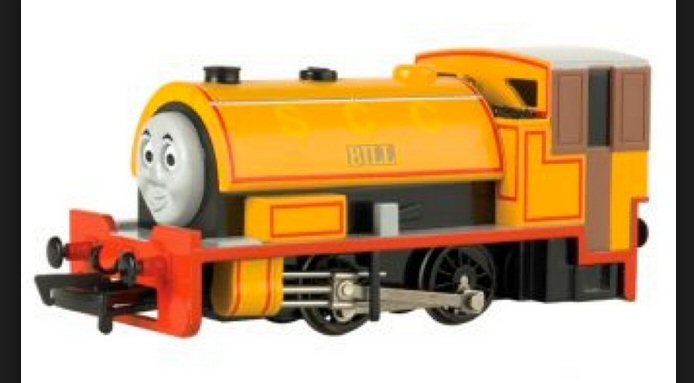

Well with the Peckett in my hands it was very obvious that there would be a lot of work. While O scale, ther was not a lot of room for a mechanism. And the loco needs clyinders, valvegear and the outside cranks, being a outside frame loco. I purchased a Bachmann porter with sound, but as it was a convential inside frame it just would not be good enough. At the 2014 Ballarat Model Railway Exhibitiion, Ken Hunter suggested Bill or Ben from the bachmann Thomas range. Purchased one but still a inside frame, and the mech was far too big. That mech went to the UK loco project. Next step was at the 2014 Stawell Model Railway Exhibition I took the 3D models for comment. I got great advice by several modellers. One suggestec a Bachmann Gas Mechanical. As it happens there was one at the show for sale agt a good price, so I snapped it up. Next was a talk to Phil Badger who gave me a lot of his time on the matter. We even pulled the loco apart there at the show to see what was possible. Phil suggested what to do in order to fot the mechanism to the body, with both needing several cuts.

|

|

|

I's now September. I decided to do more. So time to tackle the loco. Started cutting and soon realised I could cut more out of the mech as it has a inner core of plastic. So I cut the loco in half! It resulted in a smaller mech. Attention to the body. I took to it with a rotary tool and cutting disc to slice the underbelly and even the firebox. Also used some routing bits. The material acted more like stryene plastic to cut. At the moment the biggest compromise is the valvegear. Have the worling outside frame sidrods bit no rod tot he clyinder. In order to fit the new frames, the clyinders may go, so I can make some dummies out of brass tube. That would allow me to at lease solder in a none Like the real loco I do not expect this loco to be used a lot. Nor expect a big load, I would be happy with one van, perhaps two. |

|

| |

|

Page written & maintained by David Head.david@nmit.vic.edu.au